___________________________________

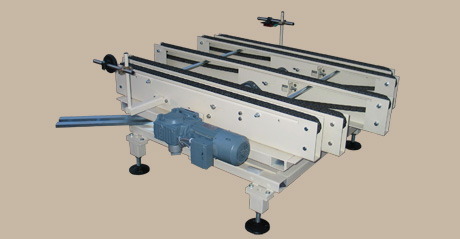

Example:

Back-up conveyor in a German brewery

- Motor-driven or pneumatic lifting device

- Double- or multi-track chain conveyor

- Direct four-sided passage possible

- Compact design

- Low maintenance

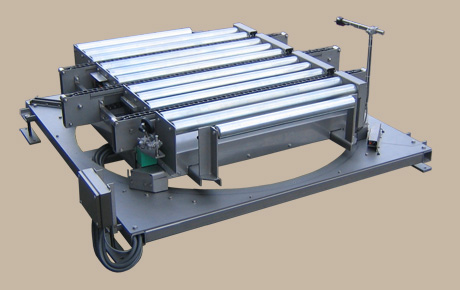

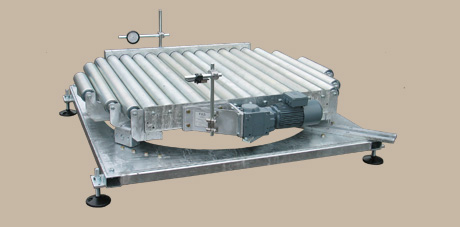

- Combination of angular transfer unit and pivoted table

- Change of direction from longitudinal travel to transverse travel or rotation of pallet

- Direct four-sided passage possible

- Available with or without stroke compensation

- Stroke of roller conveyor motor-driven or pneumatic-driven

- Compact design

- Low maintenance

- Pressure-free conveying

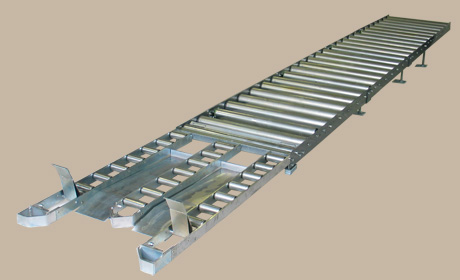

- Modular concept offers three standard coveying widths

- Longitudinal or transverse run of the pallets

- Conveyor rollers with 200 mm or 70 mm pitch

- robust, straight-plated pallet conveyor chain 16 B-1

- Control concept with photoelectric sensors or contact rollers

- Optional stainless steel design

- Compact design

- Low maintenance

- Design depending on transport goods:

- double-tracked for empty pallets and empty pallet piles

- triple-tracked for empty and full pallets

- four- and five-tracked for special pallets

- Smooth run and soft segment transitions

- Plastic slide strips for chains guarantee easy running with low wear

- Drive located in the center (underneath or sidewards)

- Integrated chain tensioner for a constant segment length

- High degree of reliability and efficiency

- Options: reversable usage, soft start, frequency control

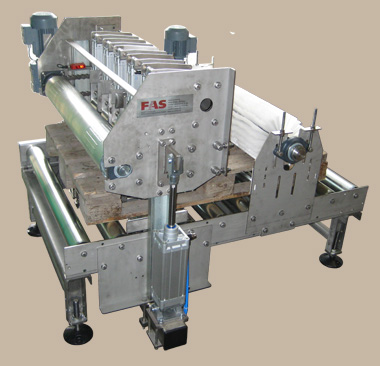

- Pressure rollers driven by geared motor, roller stroke pneumatic-driven

- Combination with burring device is possible, optional with suction cleaning device

- Infeed of the empty pallets in longitudinal direction

- Pressure of the test operation infinitely variable

- Floor running boards and floor transverse boards are checked

- Missing blocks will be identified

- Capacity up to 150 pallets per hour

- Top or lateral operation

- Transverse and longitudinal run possible

- Usable for high capacity lines

- Low maintenance

- Stable design for stackers

Centring station

- For 4-side-centring of the products on a pallet

- Suitable for crates, boxes or drums on a pallet or for stacks of empty pallets

- Suitable for roller or chain conveyor segments

- Pneumatic-driven centring with mechanical synchronization

- Wired on terminal box

- Low maintenance

- High life span

Pallet centring device

- for centering of empty pallets and loaded pallets

- optimized for FAS roller conveyor segments, integration in third party equipment possible

- can be used in connection with recognition and labeling systems

- Centering operation via pneumatic cylinders with synchronization unit

- completely wired on a connection box

- Low maintenance

- High life span

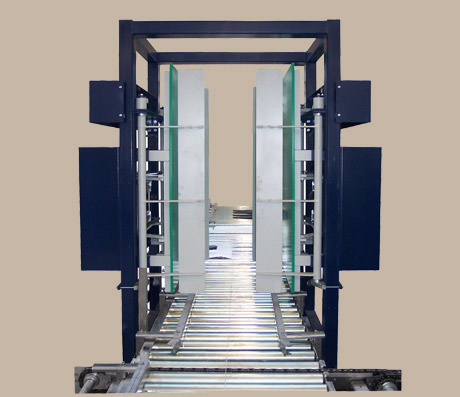

- For the connection of different floors or conveying levels

- Multiple stopping points are possible

- Variable design, e.g. as double-elevator

- Can be equipped with roller or chain conveyors

- Lifting drive unit can be positioned on top or at bottom

- Low maintenance

- High life span

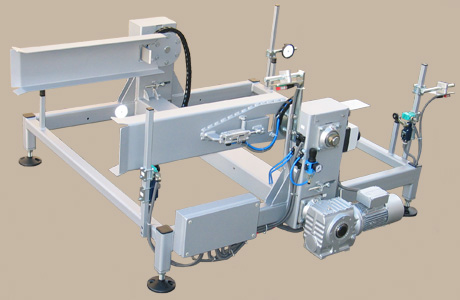

- Suitable for pushing off products from a pallet on a pack or crate conveyor

- Prepared for integration of chain or roller conveyor

- Electro-hydraulic drive system with mechanical parallel guiding

- Low maintenance

- High life span

- Type depending on production requirements:

- Stacking of pallets

- Destacking of pallets

- Stacking / Destacking of empty pallets

- Available for longitudinal and transverse pallet run

- Compact design

- Low maintenance

- Prepared for integration of roller conveyor or chain conveyor

- Displacing distance of up to 6 m

- Transfer of energy / control signals by means of cable / energy chains

- 3-phase-geared-motor with chain / sprocket wheel as drive system

- Low maintenance

- High life span

- Options: soft start, frequency control

- Prepared for integration of chain conveyor

- 180 degree turning of an empty pallet after position monitoring

- Turning driven by 3 phase-gearbox-motor

- Alignment of the pallets by stop fingers integrated in the swivel arms

- Option: Speed control by frequency converter

- for turning of empty pallets

- integrated in chain conveyor segments or roller conveyor segments

- 90 degree turns between transverse and longitudinal orientation, for example in front of a pallet inspection system

- Lifting stroke and turning via pneumatic cylinders with synchronization unit

- completely wired on a connection box

- Low maintenance

- High life span

- Double-, triple- and quintuple-tracked version

- Longitudinal and respectively transverse run of the pallet remains unchanged

- Soft start and stop of the rotation thanks to crank mechanism

- Guide rails and pallet stopper device as option

- Optional stainless steel design

- Compact design

- Low maintenance

- 90 or 180 degree change of travel direction of the pallet

- Turning drive by gear motor and sprocket / entwined chain

- Guide rails and pallet stopper device as option

- Optional stainless steel design

- Compact design

- Low maintenance

- 90 degree change of travel direction of the pallet

- Longitudinal and respectively transverse run of the pallet remains unchanged

- Soft start and stop of the rotation thanks to crank mechanism

- Guide rails and pallet stopper device as option

- Optional stainless steel design

- Compact design

- Low maintenance

Example:

Multiple infeed / discharge segment

- Suitable for pallets, boxes, crates, etc.

- Modular concept offers varying roller pitches and roller widths

- Durable roller design

- Low maintenance

- High life span

- Options: reversable usage, soft start, frequency control

Example:

Gravity roller conveyor with tripartite discharge and with seperating and stopping device

- Suitable for pallets, boxes, crates, etc.

- Modular concept offers varying roller pitches and roller widths

- Brake roller with spring suspension for speed control

- Available with tripartite discharge or as continuous version

- Seperating and stopping device available for seperation of the pallets at the discharge

- Durable roller design

- Low maintenance

- High life span